*The safety information in this policy does not take precedence over government OH&S Legislation. All employees should be familiar with the OH&S Act and other applicable legislation.*

COMPANY SAFETY POLICY

Constructive Solutions Group has a Company Safety Policy.

It is posted at our office and copies are available to everyone upon request.

This policy states:

- The personal safety and health of employees is of primary importance.

- Working safely is a condition of employment.

- Management and all employees must co-operate in all health and safety matters.

- The objective of the program is to reduce injuries and illnesses.

- We set zero injuries as our safety expectation.

- Management, supervisors, employees, visitors and customers must comply with all safety program requirements and applicable legislation.

- We will work in compliance with our client’s safety programs

- Workers will refuse to perform work that would place them or other workers in danger

RESPONSIBILITY FOR HEALTH AND SAFETY

Everyone at Constructive Solutions Group has responsibilities for health and safety.

All workers are required to:

- Read, understand and comply with the company safety policy, safe work practices, procedures and rules.

- Wear safety equipment, PPE devices and clothing as required by legislation, Constructive Solutions Group, and the worksite.

- To notify supervisor(s) of any unsafe conditions or acts that may be of danger to other workers or themselves and refuse to perform work which could cause injury to themselves or others.

- To report all accidents and injuries to their supervisor on site and to the Constructive Solutions Group as soon as possible.

- To take every reasonable precaution to protect the safety of other workers and themselves.

- Cooperate with training efforts and apply the training in the performance of their work.

As part of our commitment to the promotion and support of the physical, psychological and social well-being of our employees, Constructive Solutions has a ZERO TOLERANCE POLICY with respect to Drugs, Alcohol, Violence and Sexual Harassment on all client sites, and at the Constructive Solutions offices.

These policies include and extend to areas where Constructive Solutions staff and workers are present for the purpose of employment, transportation, in transit to/from site, and waiting on dispatch or payout.

Constructive Solutions recognizes ‘Drugs’ and ‘Alcohol’ as any substance, in any form that is illegal, legal, medically and non-medically authorized that could cause physical or mental impairment following it’s use and while under the influence. In addition to alcohol and illegal/legal drugs, the use of over-the-counter medications (ie, cold/flu and allergy medication), medical prescriptions including marijuana does not entitle an employee to be impaired at work, nor can the use of any of substance allow that employee to endanger their own safety or the safety of others.

Any worker suspected being Unfit for Work, and/or of being under the influence of drugs or alcohol:

- Will not be dispatched to a worksite that morning

- Will be removed/released from site or office immediately

- If removed from site – Pay cheque could be held for 2 weeks

- If removed from site – Employment may be terminated following an investigation of the circumstances

- May be subject to drug/alcohol testing if the suspicion follows an incident on site as Constructive Solutions will support the worksite policies of our clients.

You can not use Cannabis, Cannabis Products, Drugs or Alcohol on your way to work.

You can not use Cannabis, Cannabis Products, Drugs or Alcohol at any time during your work day.

You can not have Cannabis, Cannabis Products, Drugs or Alcohol with you on site.

Leave it at home.

To reference full policies for Drugs and Alcohol, please refer to the Health and Safety Manual.

The Constructive Solutions is committed to providing a work environment that is free of personal or sexual harassment and is supportive of the productivity, dignity and self-esteem of all employees, contractors, volunteers and students working within our organization. As such, we will not condone personal or sexual harassment by anyone to anyone having a contractual or employee link to our Company, in the workplace, at any work-related function, social or otherwise, or in any other circumstance.

Any persons under the direction of the Constructive Solutions who is found to have subjected any employee to sexual or personal harassment will be subject to progressive disciplinary measures as we deem appropriate under the circumstances, up to and including dismissal.

Definitions:

“Personal Harassment” is any unwelcome behavior, conduct or communication, directed at an individual that is offensive to that individual and is based on gender, marital status, sexual orientation, race, color, religion, origin, ancestry, age or disability. It is persistent and creates an intimidating, offensive or embarrassing work environment.

“Sexual Harassment” is any offensive sexual comment, gesture, physical contact or demand for sexual favors, which is deliberate and unsolicited. It creates an intimidating, offensive or embarrassing work environment. Sexual harassment includes behavior that the employee knows or reasonable should know is offensive. Sexual harassment does not refer to accepted social banter. However, tolerance for such behavior varies and accordingly good judgment must be exercised.

If you feel you are being harassed, either personally or sexually:

- Tell the individual that his/her behavior is unwelcome and ask him/her to stop.

- Keep a record of incidents, dates, times, locations, possible witnesses and your response. You do not have to have a record to make a complaint, but a record can strengthen your case and help you remember details over time.

- Do not delay in making a complaint, especially if the situation is deteriorating.

Make a complaint by reporting the situation to the Constructive Solutions office. All complaints of personal or sexual harassment will be kept strictly confidential and investigated by Constructive Solutions management.

Violence includes an attempted or actual intent of physical force as to cause injury and includes any threatening statement or behavior which gives another person reasonable cause to believe that he or she is at risk of physical, mental, or emotional injury. The existing and potential hazard of violence or harassment is included in the Constructive Solutions General Hazard Assessment.

As a condition of employment, employees are expected to refrain from causing or participating in harassment or violence and recognize and agree to adhere to this policy and all policies that are addressed in Constructive Solutions New Hire Orientation, Health and Safety Manual, our clients’ Orientations and Policies, and to follow all rules and regulations according to the OH&S Standards and other Regulatory Agencies.

Constructive Solutions has a ZERO TOLERANCE POLICY with respect to all 4 types of Workplace Violence on all client sites, and at the Constructive Solutions offices.

- Type 1: Criminal Intent – with this type of workplace violence, the primary motive is theft. (ie, robbery)

- Type 2: Employee/Client – this type of workplace violence involves a threat of verbal or physical assault between the employee and either the employer (Constructive Solutions) or with the client at site

- Type 3: Worker on worker – this type of workplace violence is usually work-related or interpersonal conflicts among employees of either Constructive Solutions, or client employees/3rd party employees at site

- Type 4: Personal Relationship, this type of workplace violence often involves domestic/personal relationships of employees that leads to threats or assault at the worksite or office, and may include co-workers either directly (trying to intervene), or indirectly (via phone calls to the workers office.)

HORSEPLAY and HAZING

Horseplay or Hazing is considered a form of violence in the workplace and can result in humiliation, embarrassment, anger, hurt feelings, distrust and even a desire for revenge. It is recognized and can refer to any unsafe act that is caused by an individual usually seen as ‘it’s all in the name of fun”. These unsafe acts include but are not limited to: Pranks, Practical Jokes, Unauthorized Competitions/Contests.

INCIDENTS OF VIOLENCE must be reported, investigated, and documented. In the event of a workplace violence incident, employees should:

- Ask them to stop

- Keep a record of the incident(s) if possible (dates, times, location, possible witnesses)

- Report it.

To reference full policies for Workplace Violence, please refer to the Health and Safety Manual.

Workers shall follow all safe work and operational procedures outlined in the Constructive Solutions Health and Safety Manual, Safety Orientation Manual, all W.C.B. Industrial Health and Safety Regulations, and any applicable site-specific safe work procedures of the employer.

Failure of any worker to do so will cause them to be subject to the Disciplinary Policy as follows:

1st Offence

WRITTEN WARNING ON WORKER’S FILE

2ND Offence

WRITTEN WARNING & 3 DAY SUSPENSION

3RD Offence

TERMINATION! THE CONSTRUCTIVE SOLUTIONS GROUP WILL NO LONGER CONSIDER THIS WORKER FOR EMPLOYMENT

The Occupational Health and Safety Act gives workers the right to refuse work if they believe it is dangerous or potentially dangerous. Constructive Solutions recognizes the workers’ right to refuse dangerous work. COMMUNICATION is essential as part of the Refusal of Unsafe Work procedure and expect our workers to follow the procedure in a respectful and professional manner.

In the event that a task, situation or environment is believed to pose a serious and immediate threat to the health and safety of either the worker or workers in the area, the worker should:

- Pause Work or Task and if applicable, Remove Yourself from Unsafe Environment

- Report the hazard or unsafe situation immediately

- Wait for resolution, or confirmation that the unsafe situation has been resolved. Keep busy.

A person must not carry out or cause to be carried out any work process, or be present in a situation or environment if that person has reasonable cause to believe that to continue would create an undue hazard to the health and safety of themselves or others. Work, or operation of any tool, appliance or equipment must stop.

A worker that has stopped and refused what they believe to be unsafe work must immediately report the circumstances of the unsafe condition to the site supervisor or management. The worker must also report the Refusal of Unsafe Work to Constructive Solutions office in order to be documented and followed-up, if required.

A worker must not be subject to disciplinary action because of the reasonable reporting of an unsafe condition and every effort will be made to find the worker alternative work until the matter is resolved. The worker that has reported the dangerous or potentially dangerous work must ensure that the unsafe condition is mediated, remedied or resolved, and has received a report or confirmation of resolution.

In the event that the unsafe situation can not be immediately resolved and the worker has been assigned alternative work, Constructive Solutions must be informed of the situation. In collaboration with site management, and if required Client Corporate Safety/Project Management, Constructive Solutions will investigate the matter without undue delay and follow up with the worker.

SUPERVISION

Constructive Solutions will make every effort to ensure that employees at site have adequate direction and instruction by the clients onsite supervisor in order to facilitate the safe performance of their duties. Every onsite supervisor is responsible for the proper instruction of workers under his/her direction and control, and for ensuring their work is performed without undue risk.

CORRECTION OF UNSAFE CONDITIONS/HAZARDS

Whenever a person observes what appears to be an unsafe or harmful condition or act the person must report it immediately to a site supervisor or the Constructive Solutions office. Unsafe or harmful conditions must be remedied without delay.

FIRST AID

The client/site supervisor must supply and make available First Aid equipment, supplies and facilities, and ensure approved First Aid treatment by a qualified Occupational First Aid Attendant is readily accessible to all workers during working hours while at the clients site. This information should be given during the Site Orientation.

INJURY REPORTING

All injuries, no matter how slight, must be reported to the site supervisor or First Aid Attendant for treatment. All injuries that require MEDICAL TREATMENT must be reported to Constructive Solutions office personnel WITHIN ONE HOUR.

The Site Supervisor or First Aid Attendant is required to complete a First Aid Treatment Form for all injuries requiring medical attention. A copy of the form must be delivered to Constructive Solutions Office immediately by fax or in person.

In the event that a higher level of Medical Treatment is required, the attending physician is to be informed that modified work is available in the should a return to regular work activities is not possible.

Immediately following all medical appointments, workers must report to the office of CONSTRUCTIVE SOLUTIONS and bring copies of all medical reporting.

In the event that you are injured at work, you must take the following steps:

- Report your injury to the supervisor on-site immediately.

- Report to the Constructive Solutions Group as soon as possible (WITHIN ONE HOUR).

- Go to the doctor for medical attention – advise them that the Constructive Solutions Group has modified work available – ask the doctor what activities you can do.

- After you see the doctor (on the same day, if possible) bring the medical form back to the Constructive Solutions Group Office. We will need to see the Physician’s First Report. We will need to talk with you before you leave to go home or return to work.

- You will need to complete a Worker’s Report of Accident in order to start a WCB claim. This will be provided to you and Constructive Solutions Calgary will submit your report to the WCB along with our reports.

- You will be offered modified work. This is offered to all employees who are injured at work and is available until you can return to your pre-accident level of employment. Duties will be based on restrictions and tasks allowed noted on the Physician’s First Report.

- If you are not coming in daily for modified work, YOU ARE REQUIRED TO CALL IN EVERY DAY to provide an update on your status. We would request that you call the office at 6:00 a.m. unless a different time has been agreed to.

- You must call the Constructive Solutions Group office after each medical appointment to provide an update on your status. After each medical appointment, we require you to bring in the copy of the Physician’s Report to the office along with any other information you have.

Constructive Solutions recognizes that Hazard Assessment, Elimination and Control is an essential component of a robust health and safety program. All employees, whether in the office or at a clients’ work site are expected to be involved in the hazard assessment and identification process, and in the control or elimination of safety or health hazards that have been identified.

- Safety Hazards – Potential to cause immediate injury or damage

- Health Hazards – Potential to cause an acute or chronic condition, illness or disease

Safety Hazards are mitigated via 3 Controls:

- Engineering Controls (control hazards at source/site)

- ie: Barriers/Guard Rails, Fans/Filters, Equipment Modifications

- Administrative Controls (control between hazard and worker)

- ie: Orientations, Training, Safe Work Procedures/Permits

- Personal Protective Equipment (control at the worker level)

- ie: Hard Hat, Gloves, Reflective Vest, Fall Protection, Steel Toed Boots

All workers must respect, recognize, and use all Engineering Controls installed, whether permanent or temporarily put in place by our Clients, or by others on the Client’s sites.

All workers must participate in Orientations and Training, including on-the-job training, and more the formal training for certification required for use of certain equipment or completion of certain tasks. This also includes safety meetings and completion of Task Analysis (TA), Hazard Assessment (JHA), Job Safety Analysis (JSA) and the like required at the worksite.

All workers must use and wear properly the appropriate personal protective equipment (PPE) in accordance with policies addressed in Constructive Solutions New Hire Orientation, Health and Safety Manual, our clients’ Orientations and Policies, and to follow all rules and regulations according to the OH&S Standards and other Regulatory Agencies.

There are many types of hazards, if you encounter anything that looks to be a potential hazard then it must be reported immediately.

To reference full policies for Hazards and Prevention, please refer to the Health and Safety Manual.

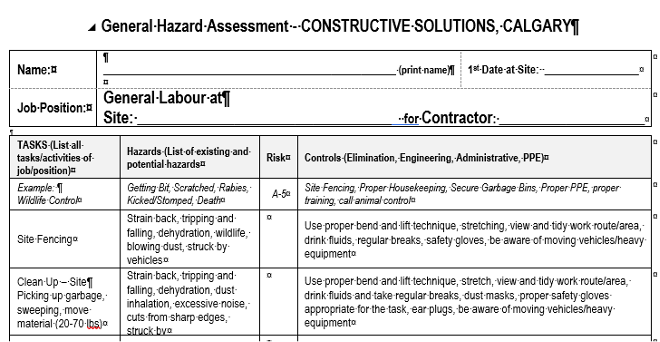

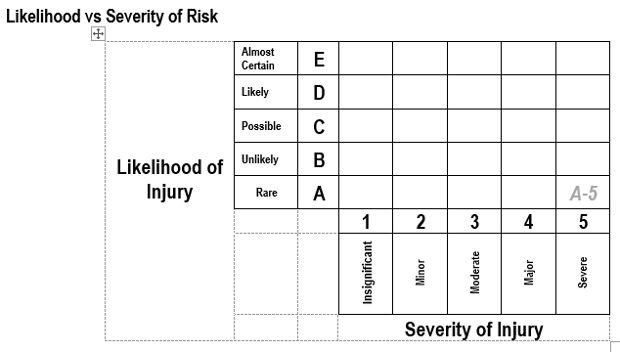

GENERAL HAZARD ASSESSMENT

A General Hazard Assessment will be completed at the Constructive Solutions office and references general hazards for possible tasks that could be done based on the position. Once at site, workers may be required to complete Hazard Assessments, Job or Task Hazard Assessments based on our clients safety program.

The following is a list of potential hazards that may be present at a job site, but not limited to:

- Slippery walking surfaces (Slipping)

- Debris, materials, equipment on floors, stairs or walkways (Tripping)

- Improper lifting of heavy items (Back Strain)

- Severe Weather (Winds, Cold/Hot Affects to Health)

- Improperly Secured Machinery or Safety Guards (Injury)

- Improper Use or Poorly Maintained Equipment (Injury)

- Bad Lighting (Injury, Tripping, Eye Strain)

- Falling objects (njury)

Overexertion is one greatest causes of injury in the workplace. Follow these guidelines for safe lifting:

- If equipment is available for lifting and transferring objects, make sure you use it. If you don’t know how to use the equipment, ask for training and assistance.

- Clear your path, make sure there is nothing in your way that could trip or hinder your movement

- Plan your lift. Size up the item before you try to lift it and try to gauge its weight.

- Get help for heavy or awkward loads. Do a team lift or obtain mechanical help such as a handcart.

- Get close to the load squat down. Bend your knees, not your back. Lift the load by straightening your legs.

- Continue to breathe normally during all lifting and carrying activities.

- To put the load down when you reach our destination, reverse the procedure. Squat down again, bending your knees and not your back.

- Do not twist your body while you are carrying an object. Move your feet, not your body, to turn.

Here are some reminders about taking care of your back:

- Maintain neutral back posture.

- When standing for long periods of time shift your weight frequently.

- Sit up straight, maintaining the natural curves in your back. Change positions regularly.

- Avoid lying on your stomach which can put stress on your back. Sleep on your back or your side with knees bent.

- Maintain a healthy weight for your height to reduce the strain on your back.

- Get regular exercise after consulting with your physician.

HEAD PROTECTION

- All workers must wear a CSA approved Hard Hat at all times while on site.

- All hardhats must be worn with the peak facing forward.

- Prior to putting on a hardhat inspect it inside and out, look for cracks or signs of damage – if it is cracked, damaged, or expired – you need to get a different hardhat.

- If you are unsure whether or not a hat is required, wear it until you can ask someone.

FOOT PROTECTION

- All workers must wear CSA approved work boots at all times while on site.

- All CSA approved boots must have a 6-inch ankle support with the green triangle visible on the boot. Steel toed shoes are NOT acceptable.

- Workers must ensure that his/her boots are in good condition with steel-toes securely in place and no dangling leather or laces that could lead to tripping.

- If the steel toe cap is exposed, the boots must be replaced.

APPEARANCE/CLOTHING

- Appropriate clothing must be worn at all times while on site.

Required and appropriate clothing for all client sites:

- Hi-Visibility Vest, T-Shirt or Jacket that has Reflective Strips

- Long or ¾ Length Sleeve Shirts (without offensive slogans or logos)

- Long Pants (no shorts)

Also appropriate articles for clothing appearance:

- Work overalls, coveralls and bib coveralls

- Hoodies (without offensive slogans or logos)

- Examples of clothing and appearance that are not acceptable:

- Hi-Visibility Straps (must be a vest at minimum)

- Tank tops / muscle shirts

- Shorts

- Loose / baggy clothing

- Jewelry such as necklaces and earrings that dangle loosely

- Long hair that has not been tied-back

HAND PROTECTION

- Workers are required to have with them and use personal protective equipment clothing that specifically protects hands, arms and depending on task, legs and torso as well.

- Gloves – types and styles are at the discretion of the worker but should be appropriate to the type of work task and the hazards identified (slivers, nails, pinches)

- Where necessary, gloves required for skin protection against the use of controlled products covered by WHMIS (concrete products, caulking, solvents, etc) should be available and used. Refer to the hazard assessment or MSDS for information on what type of gloves should be worn.

EYE PROTECTION / CONSERVATION

- Constructive Solutions expects all workers to have and properly wear CSA approved eye/face protection while at site, and if the worker is in an area of the workplace or performing a task where one or more hazards involving the eyes or face exist, or are created due to conditions or activities conducted in the area.

- Constructive Solutions supports our clients policies regarding the use of protective eye/face equipment (ie: Safety Glasses or Goggles).

- Eye protection that meets approved CSA standard is available for purchase at the Constructive Solutions office. If the worker wears prescription glasses, CSA approved glasses-over-glasses are also available.

- Workers performing tasks such as grinding, or hammering must wear protective eye wear, and depending on the task, face protection as well.

- Workers who encounter active grow rooms should limit exposure limits and must use sunglasses as protection

HEARING PROTECTION / CONSERVATION

- Workers who encounter noise levels above permissible exposure limits must use hearing protection such as ear plugs or earmuffs

- Hearing protection must be worn whenever working with or near any heavy equipment or power tools

- Read the package for instructions on how to properly insert earplugs or ask someone for instruction.

- Improperly inserted earplugs are not effective and can damage your ears.

- Prolonged exposure to elevated noise levels can result in noise induced hearing loss.

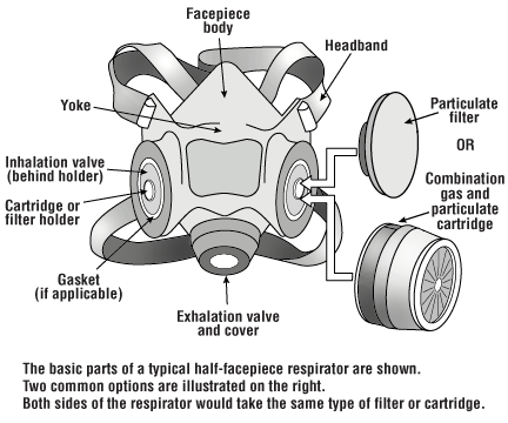

RESPIRATORY CODE OF PRACTICE

The employer must provide appropriate respiratory equipment if a worker is, or may be, exposed to concentrations of air contaminants in excess of acceptable exposure limits, or an oxygen deficient atmosphere. Some examples of respiratory protection include:

- Adequate ventilation

- Dust masks

- NIOSH respirators (National Institute of Occupational Safety and Health)

- Air purifiers

- Fit testing on site

Some situations that may require the use of respiratory protection include:

- Clean-up / sweeping (dusts /mists) – use N95 respirator

- Concrete work, chipping / drilling / grinding—use ½ mask respirator with P100 filter

- WHMIS (solvents / glue / caulking) – use ½ mask respirator with replaceable cartridges

- Power tools, cutting / sanding / grinding – use N100 respirator

When working in multiple employer workplaces, the air contaminants created by individual trades may be a hazard to all workers on site.

If you are concerned about exposure to any dusts, mists, fumes or particles, report this to a supervisor and ensure that you are wearing an appropriate respirator that you have been fit tested for.

Facial hair, scaring and some medical conditions could prevent you from wearing a respiratory device safely. Ensure that you are clean shaven if you must wear a respirator. If you have any medical conditions or psychological reasons, please discuss this with your doctor prior to wearing a respirator.

RESPIRATOR CARE

Checklist For Care of Respirators

- Inspect the respirator before and after each use and during cleaning.

- Inspect equipment designated for “emergency use” at least monthly, and after each use.

- Replace all parts that are cracked, torn, broken, missing or worn.

- Follow the manufacturer’s instructions and consult CSA Standard Z94.4-11 Selection, Care and Use of Respirators for information on the care, maintenance, and storage of respirators.

Face-Piece

- Ensure that no holes or tears are present.

- Inspect for cracked, scratched or loose-fitting lenses. For a full face-piece respirator, check for missing mounting clips.

- Ensure that the metal nose clip forms easily over the bridge of the nose on disposable respirators.

- Make sure the face-piece edges are not rippled or distorted.

Head Strap/Harness

- Check webbing for breaks.

- Look for deterioration of elasticity or fraying edges.

- Test excessively worn head harness.

Inhalation And Exhalation Valves

- Ensure the valve and valve seat are free of dust particles or dirt that may cause a poor seal or reduce efficiency.

- Replace any missing or defective valve covers.

Filter Elements

- Ensure that the filter and mask are certified for use together.

- Check the filter to see that they are approved for the hazard.

- Inspect both the filter threads and face-piece threads for wear, make sure they are screwed together properly, and there is no cross threading.

- Check the filter housing for cracks or dents.

- Check the end of service life indicator for masks. Check the expiration date.

Repair, Cleaning and Storage

- Do not clean with solvents.

- Follow the manufacturer’s instructions.

- Wash with a mild dish detergent or a combination of detergent and disinfectant. Use a brush and warm water (49-60ºC or 120-140ºF).

- Rinse with clean water, or rinse once with a disinfectant and once with clean water. The clean water rinse removes excess detergent or disinfectant that can cause skin irritation or dermatitis.

- Dry on a rack or clean surface or hang from a clothesline. Position the respirator so that the face-piece rubber will not “set” crookedly as it dries.

- Store the respirator at the end of each shift in a sealed bag to protect it from dust, sunlight, heat, extreme cold, excessive moisture, and chemicals.

- Clean and disinfect respirators after each use, where appropriate.

- Permit only trained and qualified personnel to repair respirators.

- Do not mix parts from different manufacturers.

- Record all repairs and inspections.

- Remove dirt.

- Check for distortion caused by improper storage.

FALL HAZARD AREA

A Fall Hazard Area is any area where from which a fall of 10ft or more may occur or where a fall from a lesser height involves an unusual risk of injury.

No worker shall enter a FALL HAZARD AREA unless trained in FALL PROTECTION PROCEDURES under the direct supervision of the employer on site.

Any worker working with a harness near or around a Fall Zone must be certifiably trained.

Fall hazard areas include:

- Roofs – Ladders / Saw Horses

- Decks – Elevated Work Platforms

- Scaffolding – Any fall over 10’ or unusually dangerous

Some methods of FALL PROTECTION include:

- Guardrails/Barricades

Any hazardous area that has been protected by guardrails or barricades means “KEEP OUT”

- Control Zones

An area defined by high visibility warning tape or flagging under the control of a safety monitor. Warning tape, flagging, signage or other hazard recognition systems means

“KEEP OUT” and “KEEP AWAY”

FALL PROTECTION PLANS ON SITE:

The site employer must have a written FALL PROTECTION PLAN before a worker is allowed into an area where a risk of falling exists, the employer must ensure the worker is instructed in the Fall Protection System for the area and the procedures to be followed. Fall Protection Systems can include:

- GUARDRAILS

- HARNESSES AND SAFETY BELTS

- CONNECTING EQUIPMENT

- ANCHORS

- VERTICAL AND HORIZONTAL LIFELINES

- SAFETY NETS

- CONTROL ZONES AND PROCEDURES

- RESCUE PROCEDURES

YOU ARE NOT PERMITTED TO WEAR A HARNESS WITHOUT HAVING RECEIVED PROPER TRAINING AND BEING APPROVED BY THE CONSTRUCTIVE SOLUTIONS GROUP.

DO NOT PERFORM WORK WHERE A FALL HAZARD IS PRESENT UNLESS ALL ASPECTS OF THE FALL PROTECTION AND RESCUE PLAN HAVE BEEN DISCUSSED WITH YOU.

NO WORKER IS REQUIRED TO ENTER AN AREA WHERE A FALL HAZARD EXISTS.

In industry, there are many chemicals or materials used that can be hazardous to your health and all workers should have access to information on products used and effects they may have.

WHMIS

The three key elements or aspects of information delivery are:

- Labeling (Symbols). Alerts workers to the hazards and safe procedures necessary for the handling of products.

- Material Safety Data Sheet (M.S.D.S). An MSDS is a technical bulletin, which provides detailed information on a product.

- Education.

-

- How WHMIS works

- Hazard Education

- Training in safe work procedures

WHMIS (Workplace Hazardous Materials Information System) uses classifications to group chemicals with similar properties or hazards. The Controlled Products Regulations specifies the criteria used to place materials within each classification. There are six (6) classes although several classes have divisions or subdivisions. Each class has a specific symbol to help people identify the hazard quickly.

| The Symbol Represents | It means that the material | And that you should |

| Class A

Compressed Gas

|

|

|

| Class B Combustible and Flammable Material

|

|

|

| Class C

Oxidizing Material

|

|

|

| Exclamation Mark (May causes less serious health effects or damage the ozone layer)

|

|

|

| May cause or be suspected of causing serious health effects.

|

|

|

| Class E

Corrosive Material

|

|

|

| Explosion or reactivity hazards

|

|

|

If you see one of the symbols on a product in your workplace be sure to review the MSDS for that product. The MSDS will provide you with important information on the risks of the product, and how to protect yourself. WHMIS updates are available online. Please consult online updates for new changes.

Material Safety Data Sheets (MSDS)

The Material Safety Data Sheet (MSDS) is the basic source of information about chemicals you are using in the workplace. It is part of a chemical hazard communication program that includes training and proper labeling of substances. By referring to the MSDS, you can learn why the substance is hazardous and how to protect yourself.

When you read an MSDS, you learn these important facts:

- What the chemical is.

- What company manufactures the chemical. Why the substance is hazardous and its harmful effects.

- How to use, store and dispose of the substance safely.

- How to protect yourself from exposure.

- What to do in an emergency.

For you, perhaps one of the most important part of the MSDS is the section on first aid.

When handling chemicals, remember these safety guidelines:

- Read the label. This will tell you the kind of substance in the container, what its hazards are and how to protect yourself.

- Follow exactly the directions for handling a chemical. Never mix chemicals together unless it is safe to do so, based on product information. Also, never mix chemicals with water unless you know you should because some chemicals will react violently when mixed with water.

- Store chemicals correctly, as specified on the MSDS and label. There must be adequate ventilation, the proper temperature, spill containment devices and other provisions.

- Know how to safely dispose of chemicals. This information will be included on the label and the MSDS for each chemical.

- Use the right Personal Protective Equipment (PPE). Review the MSDS to find out specific types of eye/face, hand, and respiratory protection as well as any other special requirements.

- Learn how to fight a small fire.

- Get training in first aid. Know how to help yourself and others in case of accidental exposure.

- Learn the location and operation of safety showers and eyewashes in your work area.

EDUCATION

A. When encountering controlled products that are covered by WHMIS ensure that you understand the WHMIS safe work procedures for each product before use or entering an area where they are being used.

B. Hazard Education. All areas of work, duties performed, and products used have specific health hazards and safe work procedures and all individual employers are responsible for making workers who may encounter these health hazards aware of their existence and location.

C. All individual employers at all work site locations are responsible for the training of workers in safe work procedures for any WHMIS controlled products used or hazardous environments created or encountered.

WHEN IN DOUBT ASK SOMEONE BEFORE YOU USE THE CONTROLLED PRODUCT. YOU ARE PRIMARILY RESPONSIBLE FOR YOUR OWN HEALTH AND SAFETY. NO ONE CAN PROTECT YOU BETTER THAN YOURSELF.

Emergency Preparedness means having a plan in place that we hope we will never have to use.

Every worksite must have a plan in place for dealing with emergency situations and this important information should be part of the SITE ORIENTATION.

Be sure to ask for a site orientation as soon as you arrive on a worksite so that you are aware of the following:

- Location of Emergency Equipment and Information such as:

- Fire extinguishers

- First aid supplies and treatment

- Location of Communication device(s) and contact numbers for outside assistance

- Location of MSDS sheets

- Escape routes and muster point

- Emergency phone numbers

- Emergency Procedures – In the event of an Emergency

- What are first steps on site to do

- Who to contact on-site

- Where to report to and what to do when you get there

If there is an emergency while you are in the Constructive Solutions Group office, please follow the direction of one of the employees, they will direct you to the nearest safe exit and to the muster point.